Susan Bernard was at a NASA Tech Days event in Cleveland when she saw something that caught her attention.

“They were describing sensor technology,” said Bernard, who at the time had a five-month-old son. “I was able to connect with the sensor characteristics, and on the spot I said, we can translate this technology to a common, everyday thing, and he said ‘what are you thinking?’

“And I said, well, I have a baby at home, and I would really like to know if he soiled his diaper, and what is his breath rate,” she replied.

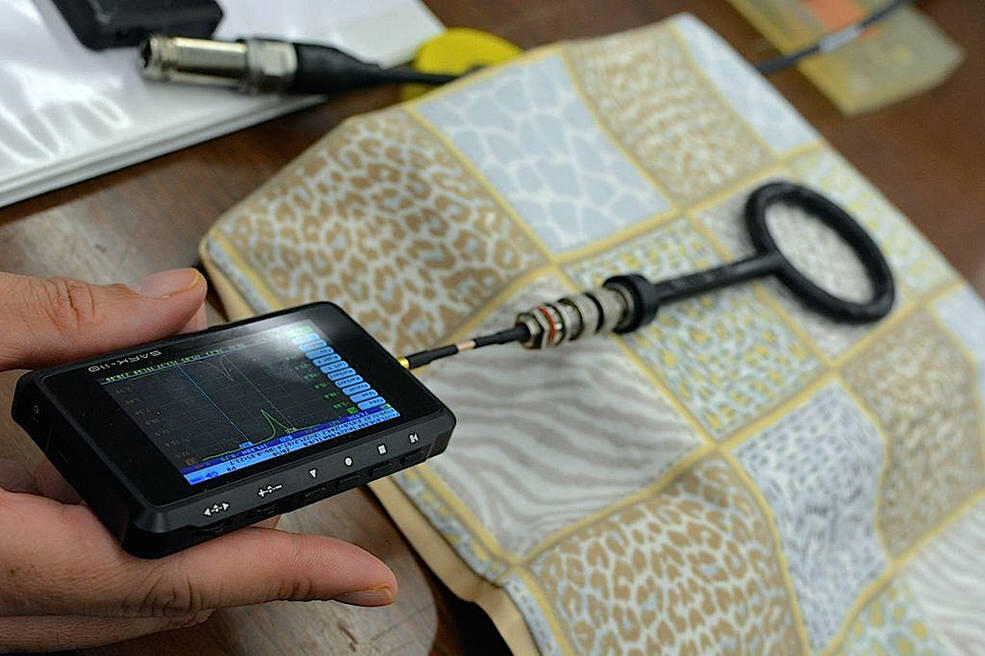

Textile Instruments is now a NASA licensee for a technology called SansEC, which is short for “without electrical connection.” It’s a sensor that functions using electromagnetic vibrations in the air. For the sensor itself, there is no need to plug it in or use batteries.

With various embroidery techniques and a multitude of fabrics, the sensors can be virtually added to existing materials, uniforms or weaved directly, creating a highly resonant sensor at a low cost with no additional weight.

Bernard and her small company in Perrysburg, Ohio, are incorporating SansEC sensors into textile products — things made of cloth and paper. A SansEC sensor, she said, can range in size down to something small enough to become a virtually undetectable part of the fabric in clothing, bedding, or diapers, for example.

Textile Instruments, she added, already has made a prototype blanket. “We’re able to detect moisture, temperature, and movement,” Bernard said, “and we recently know how to interrogate the sensor to read heart rate. We’re still very much in the R&D on the heart rate.”

“The challenge is to find uses for the sensors, creating viable products we will use daily as consumers. Our recent communications with venture-capital firms indicate they are clamoring for real prototypes. There is a demand for hardware and we have a viable path to produce them,” Bernard said.

Small package, big surprise

“It’s a very simple thing – and it’s so simple, it’s easy to miss the power of it,” said Ken Dudley, a researcher in the Electromagnetics and Sensors Branch at NASA’s Langley Research Center who is involved with SansEC.

Of Bernard, he said: “She saw the potential of this immediately.”

Robert Donley, Textile Instruments chief technology officer, said “our next step is to work on making advancements in the technology to bring it closer to the consumer’s reach.”

Donley said future developments are centered around improving the mobility and cost of the system, as well as long-range operation, reducing hardware package size and cost, and developing software to allow system data to be read and displayed on mobile platforms.

“We see an exciting passive wireless vital signs detection system on the horizon with applications in the healthcare, sportswear, and military markets,” he said.

Originally developed by NASA Langley researcher Stanley Woodard, who passed away in 2011, SansEC can simultaneously measure different physical phenomena — temperature and fluid level, for example — and functions even when badly damaged.

A remote antenna “interrogates” the sensor and collects the measurements. Woodard initially imagined using the sensor on space systems, such as inflatable habitats or the Mars airplane.

Dudley is part of a team using SansEC sensors to study the effects of lightning strikes on composite materials like the ones used on modern aircraft. The team is also hoping to use the sensors to develop a smart skin that would sense and direct lightning to a safe point on an aircraft, or even prevent lightning from ever touching it.

Other possible uses:

- Pipelines or wells: sensors could be used to test for water levels, iron or salinity, blockages, leaks or pipe integrity

- Home security: sensors could be placed in the floors to provide motion detection

- Sidewalks, driveways and parking lots: sensors could monitor ice and snow accumulation or be used for safety and security

- Food safety: sensors could detect spoiled milk, meats, etc.

- Tires: sensors could monitor for punctures, temperature, rotation rate or wear

Advances in technology have led to an increase in the development of innovative materials of all kinds. Toward that end, President Obama in April announced an initiative to develop futuristic fabrics and textiles, helping accelerate the revival of textiles manufacturing in the U.S. The Massachusetts Institute of Technology will spearhead a new manufacturing innovation institute in partnership with the Department of Defense focused on securing U.S. leadership in revolutionary fibers and textiles manufacturing.

The new Revolutionary Fibers and Textiles Manufacturing Innovation Institute in Cambridge, Massachusetts, will combine over $75 million of federal resources with nearly $250 million of non-federal investment in innovative fabrics and textiles with novel properties ranging from being incredibly lightweight and flame resistant, to having exceptional strength and containing electronic sensors.

The institute is the eighth manufacturing hub to be awarded by the Obama administration, building on the president’s vision to create a National Network for Manufacturing Innovation.

“There’s so much to be done,” said Bernard. Her company numbers four employees, including Bernard, who said she spends a lot of time seeking investors or venture capital to fund the project.

“The next step is to recognize the journey is bigger and longer than anticipated,” Bernard said, “and systematically work towards longer-range signal processing, thus solving real issues faced in the market. We will continue to strengthen our team and seek partnerships that will accelerate smart textiles closing the gap between what is and what could be. “

Author: Michael Finneran

Source: NASA Langley Research Center