Iron is an appreciated from the nutritional point of view because it helps prevent anemia element. It is present in various foods such as cereals, vegetables, and meats. However, there are different types of chemical forms of iron (organic and inorganic) that are absorbed differently by the body. In the food industry inorganic iron can promote food rancidity.

The University of Cordoba (UCO) and Aveiro (Portugal) and private research center INESC Microsystems and Nanotechnologies (INESC-NM) Lisbon have developed a biosensor that determines the amount of inorganic iron (ferric), which can be useful for the food industry in sectors such as oil or wine.

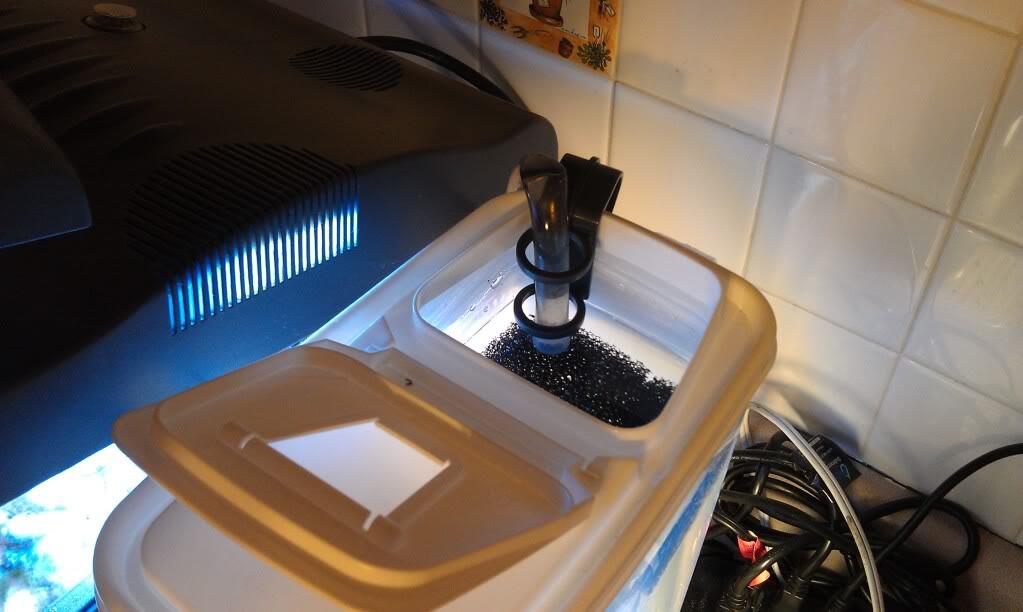

The device includes a power semiconductor, a mesh of carbon nanotubes and a support transferrinfection

Currently food analyzes are more focused to determine the type of present compound (speciation), the total quantification of them. This is because of the high degree of development of analytical chemistry. And very precise equipment developed to quantify the present compounds in many ways, the current effort of scientific equipment is to determine the chemical form in which these compounds are.

In the case of iron, there are two types, one called heme iron and other non-heme iron, which are absorbed differently.Non-heme iron is more common in plants. Non-heme iron may present as ferrous oxide [iron (II)], or ferric oxide [iron (III)]. The device developed by the research team focuses on the latter form. “The iron (III) can act as a catalyst favoring enranciamento of fats and oils, their accuracy can help determine which products have more quantity,” explains Fernando Camara, professor in the Department of Food Science and Food Technology of the UCO.

A protein as detector

Thanks to an international collaboration funded by the Iberoamerican University Postgraduate Association (AUIP), House was in contact with the group of Aveiro. an electric semiconductor (of a type called FET) on which a mesh of carbon nanotubes is provided, and a support with transferrin, a protein responsible for the transport of iron in: there the device, which is based on two parts was created living organisms.

The biosensor acts by modifying the intensity of electric current flowing through the same.

Transferrin allows detection of iron (III) in a sample, such as wine, since it binds exclusively to this iron chemical species and not others. “It has a very specific behavior, similar to what would an antibody responsible for identifying and neutralizing bacteria or virus in the body,” researcher compares the UCO.

The biosensor works by changing the electric current flowing through the same as adding experimentally a small drop of wine on the device, iron (III) present in the beverage binds to transferrin modifying this current in a way that the higher the amount of iron (III) present in the sample, the greater the decline. The results of this study are shown in Talanta magazine.

The system’s main advantage over other methods of analysis that just use chemical reagents, to determine very low amounts of chemical element and is easily disposable, so it is friendly to the environment. Another advantage, according to Chamber, is that just need sample preparation. However, the technology still needs to be scalable to be useful for the food industry. “In a second instance, could also be valid for the detection of contaminants such as heavy metals in food,” says the scientist.

Iron is an element present in both food and the human body. In men there is an average of 3.8 grams, whereas in women is 2.3 grams. Purchasing on a balanced diet prevents health problems such as anemia. It is absorbed in the greatest amount of animal origin (organic iron or iron heme) the vegetable.

Source: SINC